Diffusion Bonding

Overview

KOSTECSYS Diffusion Bonding Machine (Spark Plasma Sintering) provides an optimized solution for sintering multi-layered heterogeneous materials.

The Diffusion Bonding process offers significant advantages compared to traditional Hot Press processes, such as faster sintering, lower temperature/pressure, and shorter processing time.

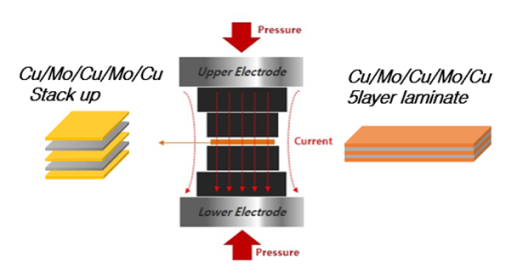

By simultaneously applying temperature and pressure while directly heating the product, the process enables rapid sintering, achieving high-density bonding materials and excellent mechanical properties with superior interfacial bonding characteristics.

Features

-

SparkPlasma Sintering

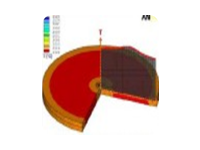

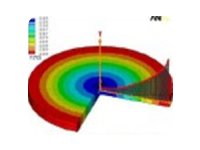

(kostec) Uniform temperature distributionVS

Uniform temperature distributionVSHotPress

(conventional) Uneven temperature distribution

Uneven temperature distribution- The composition of Mo/Cu can be customized according to your specific requirements (thermal expansion & performance)

- No adhesive is used in our diffusion bonding method

- Binders are not necessary

- Different materials (Metals, Ceramics, Composites) may be processed

- High energy efficiency & Easy operation

- Fast and Uniform sintering process

ENG

ENG  KOR

KOR