High Heat Dissipation Materials

Overview

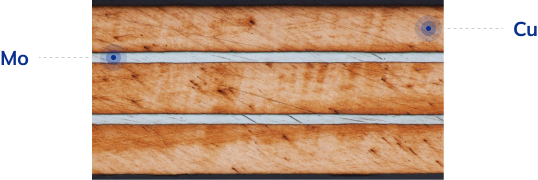

- - KOSTECSYS SPS diffusion bonding technology is a core semiconductor material technology with high thermal conductivity and low thermal expansion coefficient.

- * KCMC® (Kostec Copper Molybdenum Composite) : KOSTEC Brand, Trademark Registration - 4020240019848, Patents - 1014925220000, 1024923060000

| Material | Compositions (vol %) | Layers | Thermal Expansion [ppm/˚C] | Thermal Conductivity[W/(m.K)]25℃ (Z-direction) |

||

|---|---|---|---|---|---|---|

| Molybdenum | Copper | 150˚C | 300˚C | |||

| KCMC®12 | 12 | 88 | 3, 5, 7 | 11.05 | 9.01 | 320 |

| KCMC®20 | 20 | 80 | 9.12 | 7.69 | 291 | |

| KCMC®28 | 28 | 72 | 8.83 | 7.57 | 263 | |

| KCMC®33 | 33 | 67 | 7.83 | 6.96 | 241 | |

| KCMC®40 | 40 | 60 | 7.34 | 6.59 | 222 | |

| CPC141 | 46 | 54 | 3 | 8.20 | 7.94 | 227 |

※ The Molybdenum composition and layer can be customized according to customer requests.

Features

- Low Thermal Expansion & High Heat Dissipation

- Low Thermal Stress

- High Reliability Semiconductors

- CTE Matched Materials

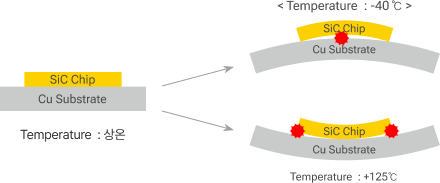

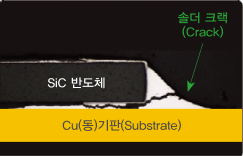

Thermal Cycle Stress caused by Thermal Mismatch

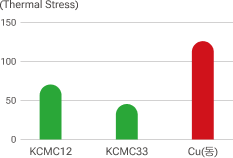

Thermal Stress in the semiconductor soldering area (Thermo-mechanical simulation data)

- Cu : Thermal Stress is “127” very high

- KCMC® : Thermal Stress is “41~69” low

Semiconductor Delamination caused by Thermal Mismatch

ENG

ENG  KOR

KOR